iPVC Plant Pipe

-

Resolves the issues of rust, corrosion, and galvanic corrosion

in Steel, Cast Iron, and Stainless-Steel Pipes -

For Industrial Plants such as Chemical Engineering, Energy,

Semiconductor, Shipbuilding, and Steelmaking

Performance of iPVC Plant Pipe

| Test Criteria | iPVC Plant Pipe | PVC Water Pipe | |

|---|---|---|---|

| International Standard (ISO4422) |

Korean Standard (KS M 3401) |

||

| Tensile Strength (MPa) | 53 | 45 | 43 |

| Drop Weight Impact Strength | 3m (9kg) | 1.6m (1kg) | 1.5m (9kg) |

| * Long term Hydrostatic Pressure (hr) | 30 | 1 | 1 |

* Conditions of Hydrostatic Pressure Test : Temp. 20°C, Tangential Stress 42.0Mpa, O.D 4’’(100mm)

Test Result of Corrosion Resistance

iPVC Plant Pipe has excellent corrosion and Wear resistance which prevents scaling and decay helping to maintain the same flow rate over the long-term.

| iPVC Plant Pipe | Criteria | Steel, Cast Iron Pipe |

|---|---|---|

| 150 | Flow Coefficient (C-factor) | Initial Installation: 130 ~ 140 |

| After 4 to 12 yrs: 120 | ||

| After 13 to 20 yrs: 100 |

Economic Feasibility

Unit: %

| iPVC Plant Pipe | Steel Pipe Sch. 80 (For Pressure) | Stainless Pipe 4.0 mm (For Industry) |

|---|---|---|

| 100 | 255 | 186 |

* Reference : Korea Price Research Center (Feb. 2020)

Test Result for Weather Resistance

- 1. UV Aging Test (QUV) max 700hr & subsequent product property evaluation

-

2. Weather Resistance: Evalaution on decreased performance of the material

when exposed outdoors for a long duration to be influenced by multiple types of weathering - 3. Material Name: iPVC Plant Pipe

| iPVC Plant Pipe | L | a | b | ΔE | Tensile Strength (MPa) |

|

|---|---|---|---|---|---|---|

| UV Evaluation Period (hr) |

Initial Stage | 66.9 | -17.5 | -20.4 | - | 54 |

| 100 | 64.2 | -18.3 | -10 | 10.7 | 55 | |

| 240 | 58.6 | -12.6 | 0.1 | 22.5 | 56 | |

| 700 | 26.8 | -0.1 | -1.8 | 47.4 | 56 | |

4. 4. Conclusion: UV exposure results in color change,

but property changes such as tensile strength are minimal.

Test Result of Chemical Resistance

Test Result of Chemical Resistance iPVC Plant Pipe has excellent chemical resistance against a wide range of chemical substances and mixtures.

- However, it can be influenced by temperature and density during use.

※R : Recommended, NR : Not Recommended, ND : no data

| Medium(s) | 22℃ | 60℃ | Medium(s) | 22℃ | 60℃ |

|---|---|---|---|---|---|

| General Chemical Substance(s) | Sulfur | R | R | ||

|

Acids, maleic, malic, oxalic, oleic, succinic, tannic, tartaric |

R | R |

Sodium-acetate, benzoate, dichromate, sulfide, thiosulfate |

R | R |

| Acetic acid, glacial | R | NR | Tail oil | R | R |

| Acetic anhydride | NR | NR | Turpentine | R | R |

| Adipic acid | R | R | Urea | R | R |

| Acetylene | R | R | Aqueous Solution(s) | ||

| Alcohols-methl. proply | R | R | Acetic acid, 10%, 20%, 80%, | R | R |

| Alcohols-see-butyl, allyl 96%, amyl | R | NR | Bleach 12$ cl | R | R |

|

Ammonium-alum, bifluorid, sulfide, thiocyanate, phophate |

R | R | Bromine water | R | R |

| Carbonic acid | R | R | |||

| Butly acetate | R | NR | Muriaric acid | R | R |

| Benzoic acid | R | R | Nitric acid, 10-60% | R | R |

| Butyl stearate | R | NR | Peracetic acid, 40% | R | NR |

| Boric acid, borax | R | R | Perchloric acid, 10% | R | R |

| Butynediol | R | NR | Sea water | R | R |

| Calcium bisulfide, hydroxide | R | R | Sulfurcid acid 3-70% | R | R |

| Carbon tetrachloride | R | NR | Sulfuric acid, 80-85% | R | R |

| Castor oil | R | R | Urine | R | R |

| Citric acid | R | R | Plasticizer(s) | ||

| Detergents | R | R | Dibutozyethyl phthalate | NR | NR |

| Dextrose | R | R | Dibutyl phthalate | NR | NR |

| Diacetone alcohol | R | ND | Dibutyl sebacate | R | NR |

| Diglycolic acid | R | R | Dioctyl phthalate | NR | NR |

| Disodium phosphate | R | R | Tributyl citrate | R | ND |

| Ethylene glycol | R | R | Inorganic Salt(s) | ||

| Ethy alcohol | R | R |

Chlorides Al, NH4, Ba, Ca, Cu, Fe, Pb, Mg Hg, K, Na, Sn, Zn |

R | R |

| Ethylene glycol mono n-butyl ether | R | ND | |||

| Fatty acid | R | R | |||

| Formic acid | R | NR |

Sulfates Al, NH4, BA, Ca, Cu, Fe, Pb, Mg Ni, K, Na, Zn |

R | R |

| Glycerine | R | R | |||

| Glucose | R | R | |||

| Glycolic acid | R | R |

Nitrates Al, NH4, Ca, Cu, Pb, Mg, Ni, K Ag, Na, Zn |

R | R |

| Heptane | R | R | |||

| Hexane | R | NR | |||

| Kerosene | R | R |

Carbonates NH4, Ba, Bi, Ca, Cu, Mg, K, Na |

R | R |

| Lauryl chloride | R | NR | |||

| Linoleic acid | R | R | Foods & Beverages | ||

| Lubricating oils ASTM #1,2 | R | R | Cane and beet sugar liquors | R | R |

| Lubricating oils ASTM #3 | R | R | Corn syrup | R | R |

| Nicotine, nicotinic acid | R | R | Fructose | R | R |

| Methyl methacrylate | R | ND | Fruit juice and pulp | R | R |

| Mercury | R | R | Liquors | R | R |

| Methyl salicylate | R | ND | Molasses | R | R |

| Mineral oils | R | R | Starch | R | R |

| Naphtha | R | R | Vinegar | R | R |

| Oils, sour crude | R | R | Vegetable oil | R | R |

| Oils-linseed, cottonseed | R | R | Wine | R | R |

| Phophoric acid | R | R | |||

Major References of iPVC Plant Pipe

(Chemical, Energy, Semi-Conduct, Shipbuilding, Steel)

• PosLx Project (POSCO, 9.1 km)

• Major Reference in Korea

Chemical Wastewater Piping, Yeosu Plant, LG Chem

Freshwater Piping, Pohang Steel Mill, POSCO

Chemical Wastewater Pipe, Asan Plant, Samsung Display

Wastewater Piping, Yeosu Plant, Kolon Water & Energy

Wastewater line, Yangsan Plant, Coca-Cola

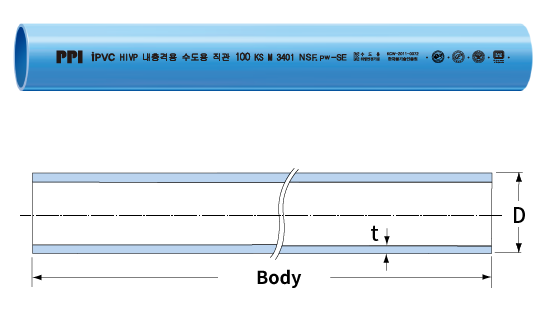

Pipe

AWWA C900

Unit : mm

| PIPE SIZE in |

AVG. O.D in (mm) |

NOM. I.D in (mm) |

MIN. T. in (mm) |

APPROX. E in (mm) |

APPROX. D in (mm) |

APPROX. WGT lbs/ft (kg/m) |

| PRESSURE CLASS 165 psi (DR25) | ||||||

| 4 | 4.80 (121.90) | 4.40 (111.55) | 0.192 (4.88) | 5.75 (146.05) | 6.19 (157.23) | 1.8 (2.66) |

| 6 | 6.90 (175.30) | 6.32 (160.44) | 0.276 (7.01) | 6.85 (173.99) | 8.62 (218.95) | 3.8 (5.48) |

| 8 | 9.05 (229.90) | 8.28 (210.43) | 0.362 (9.19) | 7.87 (199.90) | 11.02 (279.91) | 6.6 (9.42) |

| 10 | 11.10 (281.90) | 10.16 (257.99) | 0.444 (11.28) | 9.84 (249.94) | 13.54 (343.92) | 10.0 (14.19) |

| 12 | 13.20 (335.30) | 12.08 (306.88) | 0.528 (13.41) | 10.12 (257.05) | 15.84 (402.34) | 14.2 (20.06) |

| PRESSURE CLASS 235 psi (DR18) | ||||||

| 4 | 4.80 (121.90) | 4.23 (107.53) | 0.267 (6.78) | 5.75 (146.05) | 6.31 (160.27) | 2.5 (3.62) |

| 6 | 6.90 (175.30) | 6.09 (154.67) | 0.383 (9.73) | 6.85 (173.99) | 8.80 (223.52) | 5.2 (7.48) |

| 8 | 9.05 (229.90) | 7.99 (202.82) | 0.503 (12.78) | 7.87 (199.90) | 11.26 (286.00) | 9.0 (12.88) |

| 10 | 11.10 (281.90) | 9.79 (248.68) | 0.617 (15.67) | 9.84 (249.94) | 13.83 (351.28) | 13.7 (19.37) |

| 12 | 13.20 (335.30) | 11.65 (295.82) | 0.733 (18.62) | 10.12 (257.05) | 16.19 (411.23) | 19.4 (27.38) |

| PRESSURE CLASS 305 psi (DR14) | ||||||

| 4 | 4.80 (121.90) | 4.07 (103.44) | 0.343 (8.71) | 5.75 (146.05) | 6.50 (165.10) | 3.2 (4.57) |

| 6 | 6.90 (175.30) | 5.86 (148.76) | 0.493 (12.52) | 6.85 (173.99) | 9.07 (230.38) | 6.6 (9.45) |

| 8 | 9.05 (229.90) | 7.68 (195.10) | 0.646 (16.41) | 7.87 (199.90) | 11.62 (295.15) | 11.4 (16.25) |

| 10 | 11.10 (281.90) | 9.42 (239.21) | 0.793 (20.14) | 9.84 (249.94) | 14.28 (362.71) | 17.3 (24.45) |

| 12 | 13.20 (335.30) | 11.20 (284.53) | 0.943 (23.95) | 10.12 (257.05) | 16.72 (424.67) | 24.5 (34.58) |

1. Max/min outside diameter refers to the maximum and minimum values of the measured outsider diameter in a given location.

2. The average length of the pipe is 4m or 6m, and the tolerance of difference is +30/-10mm

ASTM D 1785

Unit : mm

| PIPE SIZE in |

AVG. O.D in (mm) |

NOM. I.D in (mm) |

MIN. T. in (mm) |

PRESSURE RATING (psi) |

APPROX. WGT lbs/ft (kg/m) |

| Sch. 40 | |||||

| 1 ⁄ 2 | 0.840 (21.34) | 0.602 (15.29) | 0.109 (2.77) | 600 | 0.164 (0.244) |

| 3 ⁄ 4 | 1.050 (26.67) | 0.804 (20.42) | 0.113 (2.87) | 480 | 0.217 (0.323) |

| 1 | 1.315 (33.40) | 1.029 (26.13) | 0.133 (3.38) | 450 | 0.320 (0.476) |

| 1 1 ⁄ 4 | 1.660 (42.16) | 1.359 (34.53) | 0.140 (3.56) | 370 | 0.432 (0.643) |

| 1 1 ⁄ 2 | 1.900 (48.26) | 1.590 (40.39) | 0.145 (3.68) | 330 | 0.515 (0.767) |

| 2 | 2.375 (60.32) | 2.047 (51.99) | 0.154 (3.91) | 280 | 0.691 (1.028) |

| 2 1 ⁄ 2 | 2.875 (73.02) | 2.444 (62.09) | 0.203 (5.16) | 300 | 1.091 (1.623) |

| 3 | 3.500 (88.90) | 3.042 (77.26) | 0.216 (5.49) | 260 | 1.428 (2.126) |

| 3 1 ⁄ 2 | 4.000 (101.60) | 3.521 (89.44) | 0.226 (5.74) | 240 | 1.716 (2.553) |

| 4 | 4.500 (114.30) | 3.998 (101.55) | 0.237 (6.02) | 220 | 2.033 (3.025) |

| 5 | 5.563 (141.30) | 5.016 (127.41) | 0.258 (6.55) | 190 | 2.757 (4.102) |

| 6 | 6.625 (168.28) | 6.031 (153.20) | 0.280 (7.11) | 180 | 3.581 (5.328) |

| 8 | 8.625 (219.08) | 7.942 (201.73) | 0.322 (8.18) | 160 | 5.392 (8.024) |

| 10 | 10.750 (273.05) | 9.976 (253.39) | 0.365 (9.27) | 140 | 7.644 (11.374) |

| 12 | 12.750 (323.85) | 11.889 (301.99) | 0.406 (10.31) | 130 | 10.104 (15.035) |

| 14 | 14.000 (355.6) | 13.073 (332.05) | 0.437 (11.10) | 130 | 11.961 (17.797) |

| 16 | 16.000 (406.4) | 14.940 (379.48) | 0.500 (12.70) | 130 | 15.625 (23.250) |

| Sch. 80 | |||||

| 1 ⁄ 2 | 0.840 (21.34) | 0.526 (13.37) | 0.147 (3.73) | 850 | 0.204 (0.304) |

| 3 ⁄ 4 | 1.050 (26.67) | 0.722 (18.34) | 0.154 (3.91) | 690 | 0.277 (0.412) |

| 1 | 1.315 (33.40) | 0.936 (23.77) | 0.179 (4.55) | 630 | 0.407 (0.605) |

| 1 1 ⁄ 4 | 1.660 (42.16) | 1.255 (31.88) | 0.191 (4.85) | 520 | 0.562 (0.836) |

| 1 1 ⁄ 2 | 1.900 (48.26) | 1.476 (37.49) | 0.200 (5.08) | 470 | 0.682 (1.015) |

| 2 | 2.375 (60.32) | 1.913 (48.58) | 0.218 (5.54) | 400 | 0.944 (1.405) |

| 2 1 ⁄ 2 | 2.875 (73.02) | 2.290 (58.16) | 0.276 (7.01) | 420 | 1.440 (2.142) |

| 3 | 3.500 (88.90) | 2.864 (72.75) | 0.300 (7.62) | 370 | 1.928 (2.869) |

| 3 1 ⁄ 2 | 4.000 (101.60) | 3.326 (84.48) | 0.318 (8.08) | 350 | 2.353 (3.501) |

| 4 | 4.500 (114.30) | 3.786 (96.16) | 0.337 (8.56) | 320 | 2.820 (4.196) |

| 5 | 5.563 (141.30) | 4.769 (121.12) | 0.375 (9.52) | 290 | 3.911 (5.820) |

| 6 | 6.625 (168.28) | 5.709 (145.02) | 0.432 (10.97) | 280 | 5.382 (8.009) |

| 8 | 8.625 (219.08) | 7.565 (192.16) | 0.500 (12.70) | 250 | 8.177 (12.167) |

| 10 | 10.750 (273.05) | 9.493 (241.13) | 0.593 (15.06) | 230 | 12.122 (18.037) |

| 12 | 12.750 (323.85) | 11.294 (286.87) | 0.687 (17.45) | 230 | 16.681 (24.820) |

| 14 | 14.000 (355.6) | 12.410 (315.21) | 0.750 (19.05) | 220 | 20.011 (29.776) |

| 16 | 16.000 (406.4) | 14.213 (361.01) | 0.843 (21.41) | 220 | 25.727 (38.281) |

| Sch. 120 | |||||

| 1 ⁄ 2 | 0.840 (21.34) | 0.480 (12.19) | 0.170 (4.32) | 1010 | 0.227 (0.337) |

| 3 ⁄ 4 | 1.050 (26.67) | 0.690 (17.52) | 0.170 (4.32) | 770 | 0.299 (0.444) |

| 1 | 1.315 (33.40) | 0.891 (22.63) | 0.200 (5.08) | 720 | 0.446 (0.663) |

| 1 1 ⁄ 4 | 1.660 (42.16) | 1.204 (30.58) | 0.215 (5.46) | 600 | 0.622 (0.926) |

| 1 1 ⁄ 2 | 1.900 (48.26) | 1.423 (36.14) | 0.225 (5.72) | 540 | 0.756 (1.124) |

| 2 | 2.375 (60.32) | 1.845 (46.86) | 0.250 (6.35) | 470 | 1.066 (1.585) |

| 2 1 ⁄ 2 | 2.875 (73.02) | 2.239 (56.87) | 0.300 (7.62) | 470 | 1.549 (2.305) |

| 3 | 3.500 (88.90) | 2.758 (70.05) | 0.350 (8.89) | 440 | 2.213 (3.293) |

| 3 1 ⁄ 2 | 4.000 (101.60) | 3.258 (82.75) | 0.350 (8.89) | 380 | 2.567 (3.819) |

| 4 | 4.500 (114.30) | 3.574 (90.78) | 0.437 (11.10) | 430 | 3.563 (5.301) |

| 5 | 5.563 (141.30) | 4.503 (114.38) | 0.500 (12.70) | 400 | 5.084 (7.564) |

| 6 | 6.625 (168.28) | 5.435 (138.04) | 0.562 (14.27) | 370 | 6.842 (10.180) |

| 8 | 8.625 (219.08) | 7.103 (180.42) | 0.718 (18.24) | 380 | 11.407 (16.974) |

| 10 | 10.750 (273.05) | 8.963 (227.67) | 0.843 (21.41) | 370 | 16.783 (24.972) |

| 12 | 12.750 (323.85) | 10.630 (270.00) | 1.000 (25.40) | 340 | 23.619 (35.145) |

KS M 3401

Unit : mm

| PIPE SIZE (mm) |

AVG. O.D (mm) |

NOM. I.D (mm) |

MIN. T. (mm) |

NOM. PRESSURE | APPROX. WGT (kg/m) |

PIPE END (LENGTH) |

| 13 | 18.00 | 14.40 | 1.60 | PN20 | 0.128 | PE (4,000) |

| 16 | 22.00 | 17.60 | 2.00 | PN20 | 0.191 | PE (4,000) |

| 20 | 26.00 | 20.70 | 2.40 | PN20 | 0.272 | PE (4,000) |

| 25 | 32.00 | 25.70 | 2.90 | PN20 | 0.399 | PE (4,000) |

| 30 | 38.00 | 30.40 | 3.50 | PN20 | 0.571 | PE (4,000) |

| 35 | 42.00 | 33.80 | 3.80 | PN20 | 0.683 | PE (4,000) |

| 40 | 48.00 | 38.50 | 4.40 | PN20 | 0.903 | PE (4,000) |

| 50 | 60.00 | 50.50 | 4.40 | PN16 | 1.154 | BE (6,000) |

| 65 | 76.00 | 64.00 | 5.60 | PN16 | 1.846 | BE (6,000) |

| 75 | 89.00 | 75.10 | 6.50 | PN16 | 2.507 | BE (6,000) |

| 100 | 114.00 | 99.70 | 6.70 | PN16 | 3.358 | BE (6,000) |

| 125 | 140.00 | 122.50 | 8.20 | PN16 | 5.049 | BE (6,000) |

| 150 | 165.00 | 144.40 | 9.70 | PN16 | 7.005 | BE (6,000) |

| 200 | 216.00 | 189.10 | 12.70 | PN16 | 11.976 | BE (6,000) |

| 250 | 267.00 | 233.80 | 15.70 | PN16 | 18.273 | BE (6,000) |

| 300 | 318.00 | 278.50 | 18.70 | PN16 | 25.894 | BE (6,000) |

| 350 | 355.00 | 319.30 | 16.90 | PN12.5 | 26.456 | BE (6,000) |

| 400 | 400.00 | 359.60 | 19.10 | PN12.5 | 33.726 | BE (6,000) |

| 450 | 450.00 | 404.60 | 21.50 | PN12.5 | 42.640 | BE (6,000) |

| 500 | 500.00 | 449.60 | 23.90 | PN12.5 | 52.598 | BE (6,000) |

| 630 | 630.00 | 566.80 | 30.00 | PN12.5 | 83.126 | BE (6,000) |

1. The average length of a pipe is 6m + length of the bell.

2. Outer Diameter (D) and tolerance depend on the on the pipe (PE)

3.ℓ's tolerance is +30/-10mm

4.t's tolerance depends on the pipe (PE)

5. Applied gasket is Anger Lcok, Turner Gasket, and Turner Lok

Fittings

Click on each product to see the details.

-

popup Open

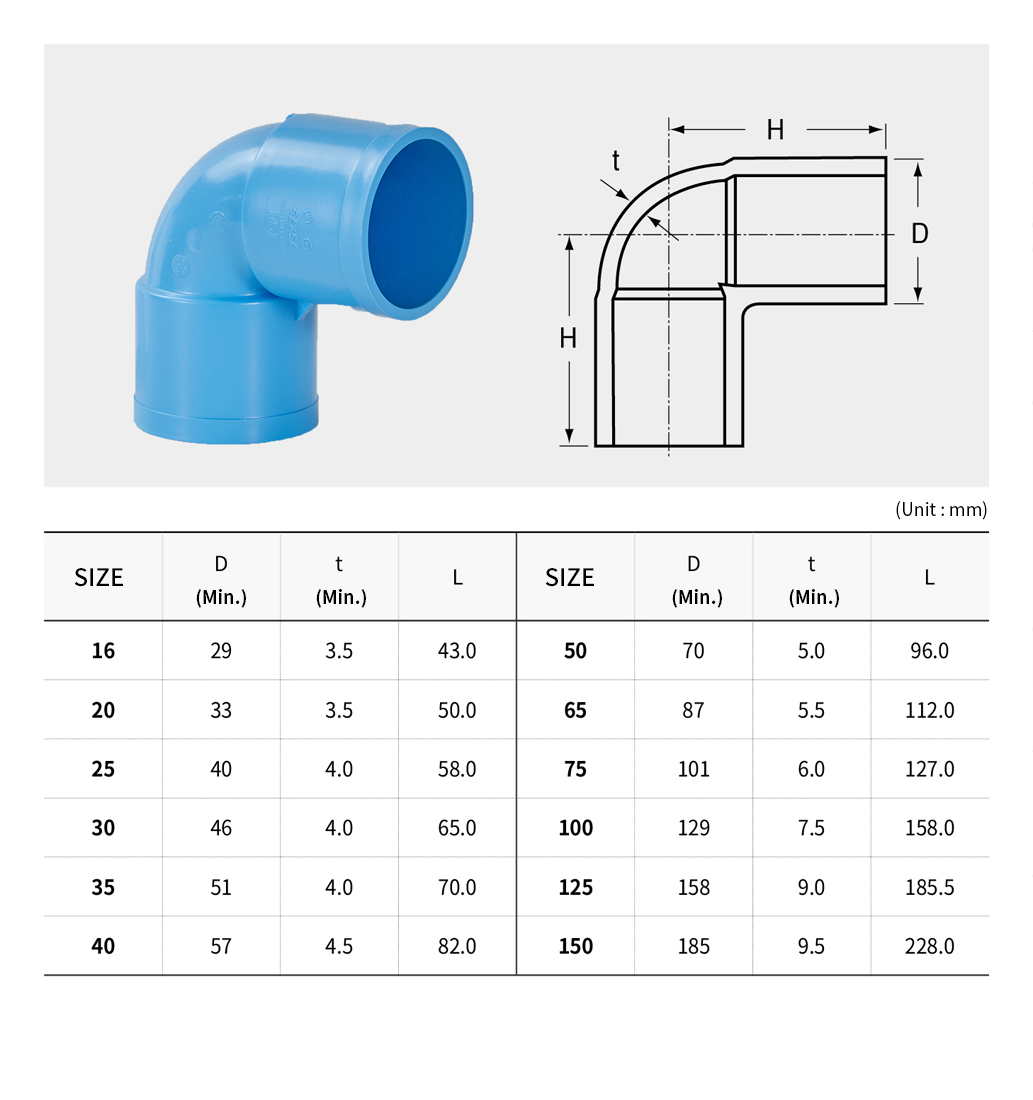

HITS-90º ELBOW

-

popup Open

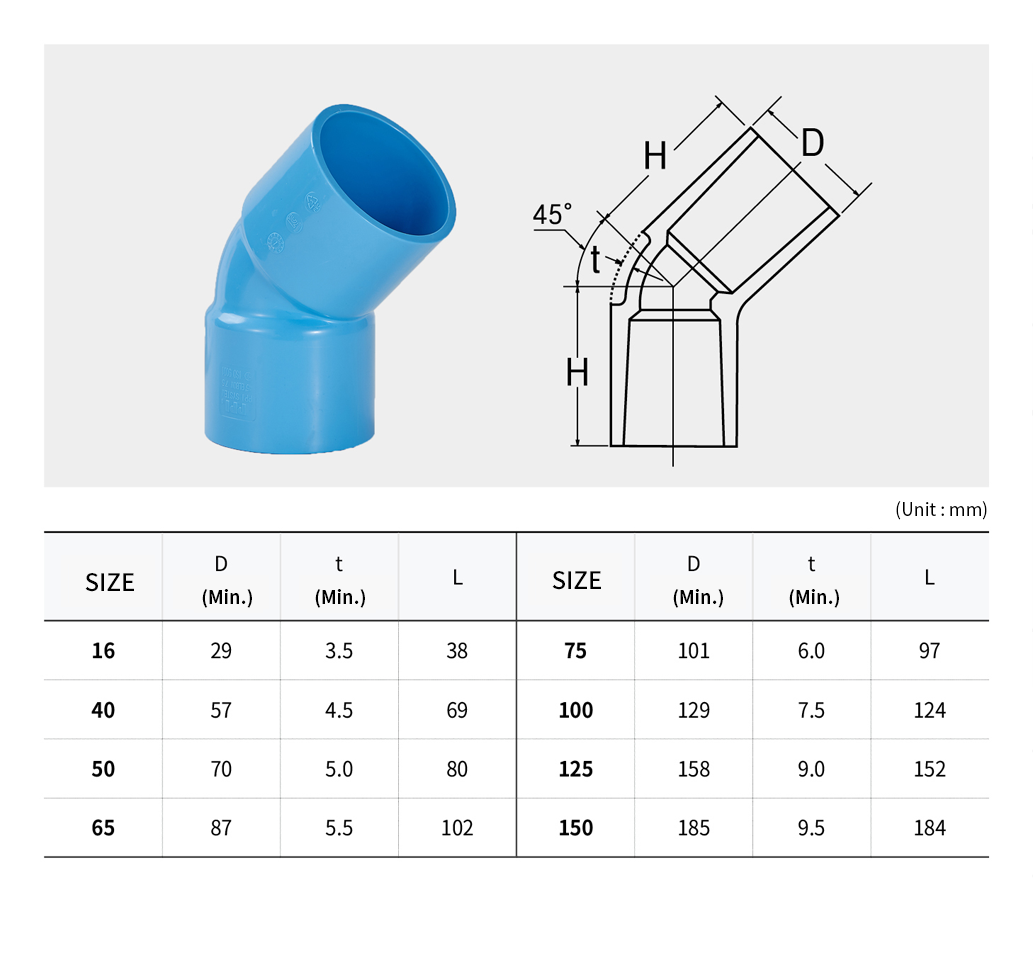

HITS-45º ELBOW

-

popup Open

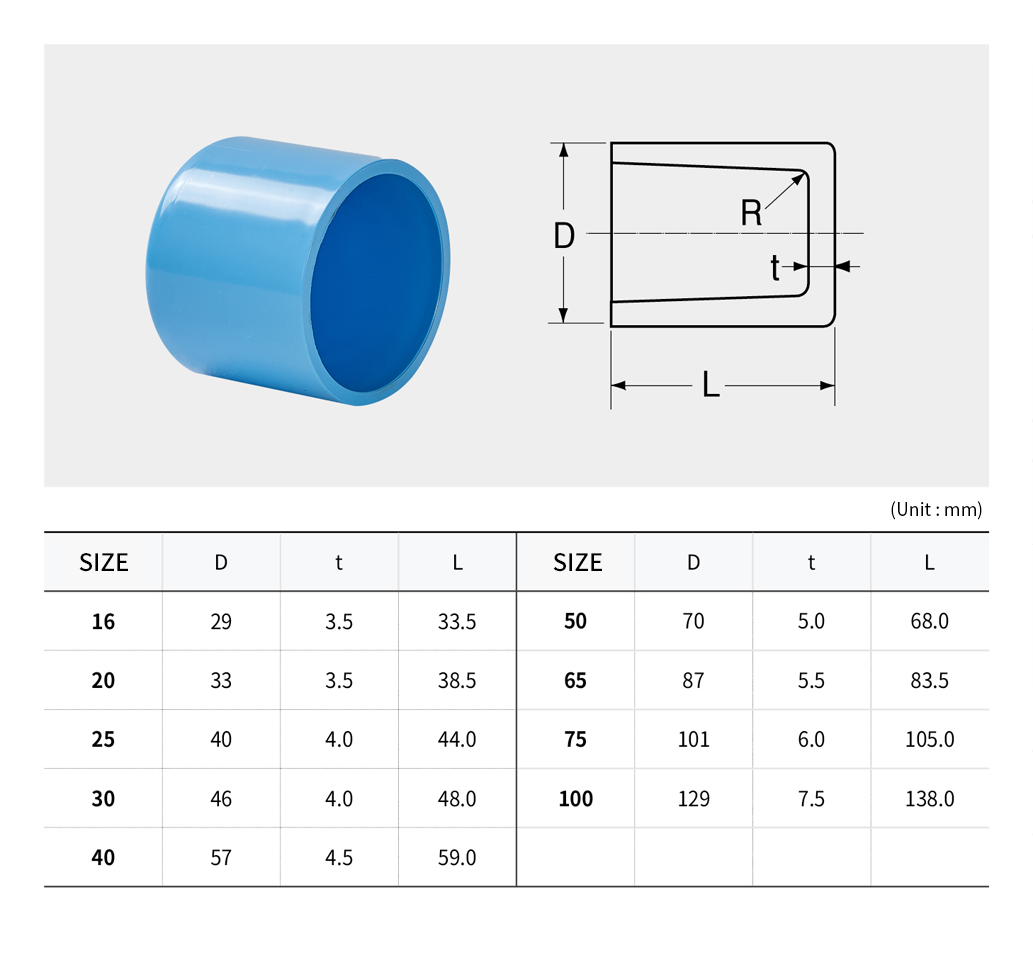

HITS-CAP

-

popup Open

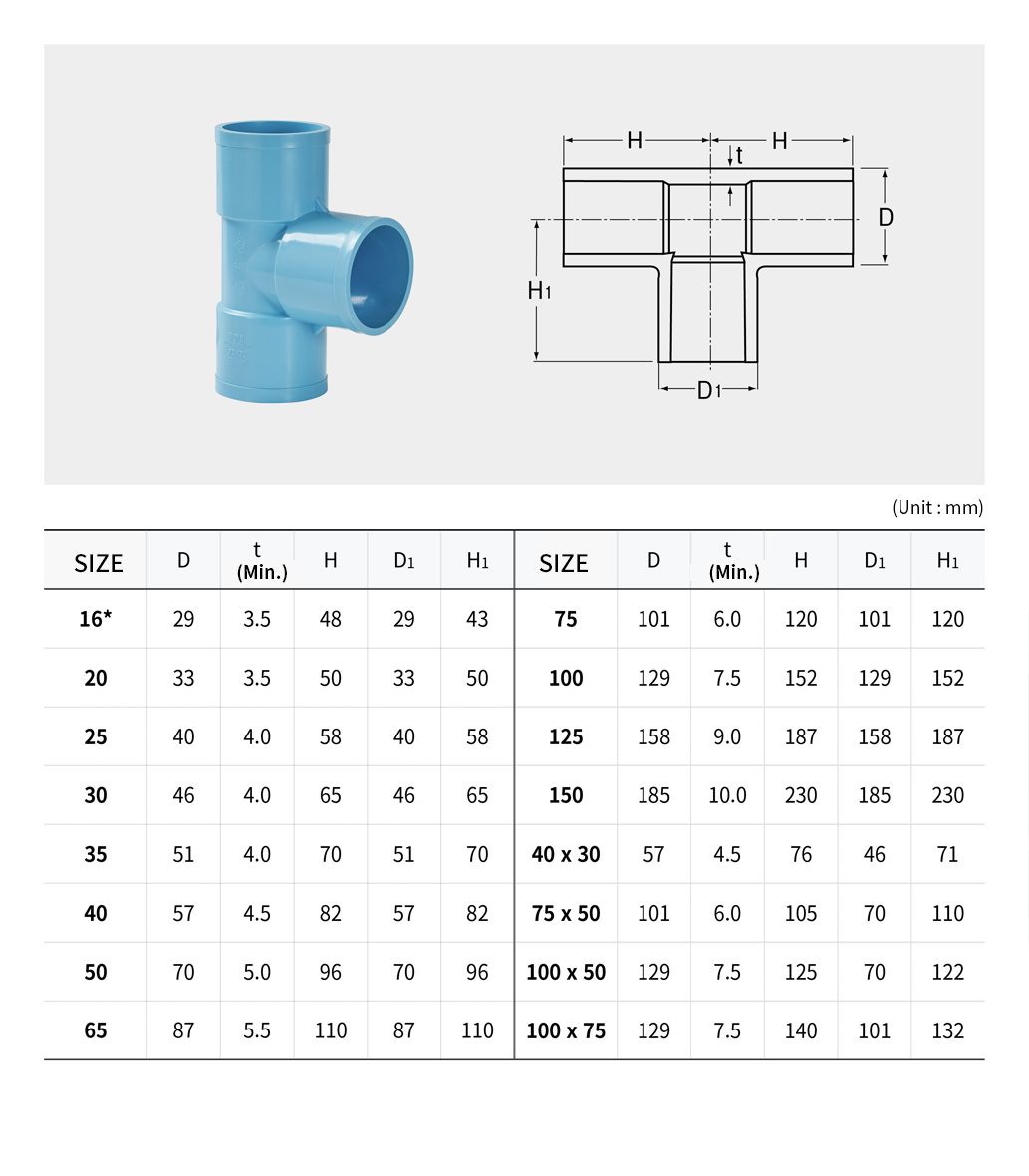

HITS-TEE

-

popup Open

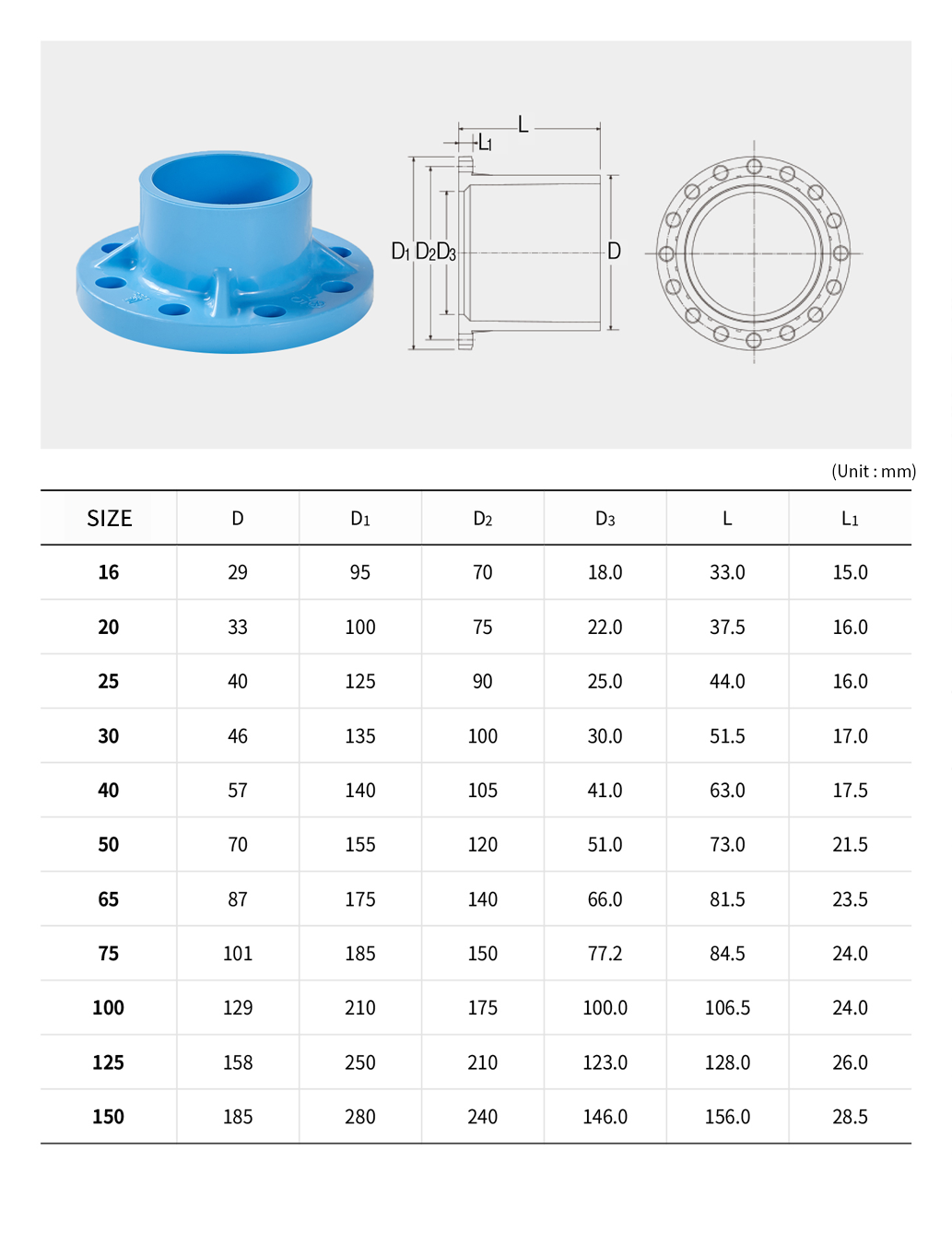

HITS-FLANGE

-

popup Open

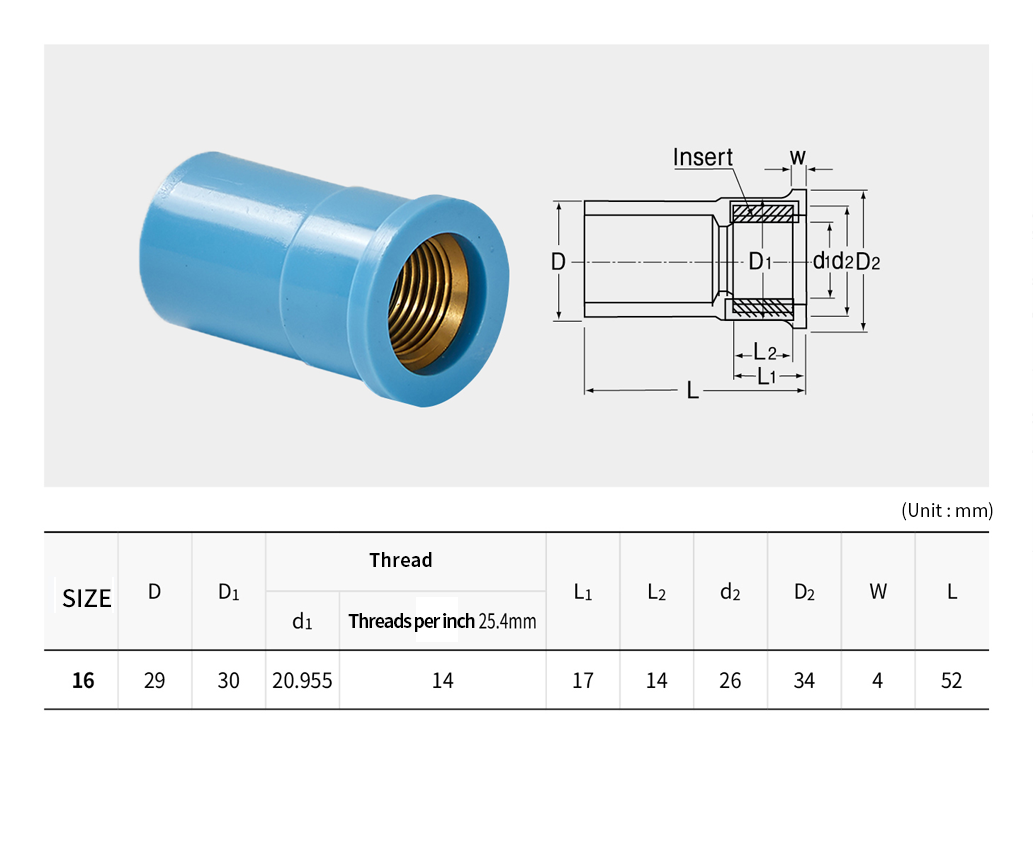

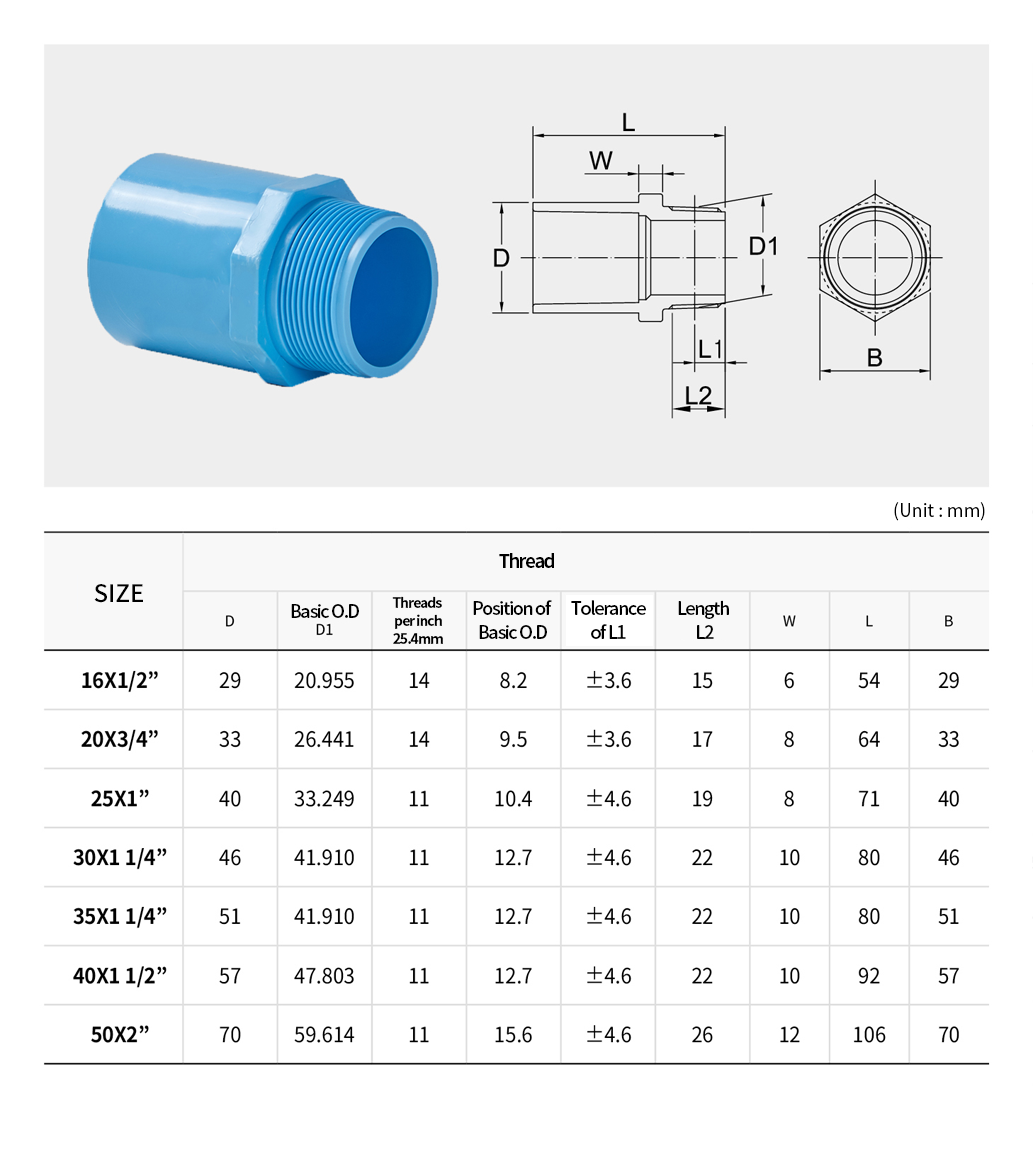

HITS-FS

-

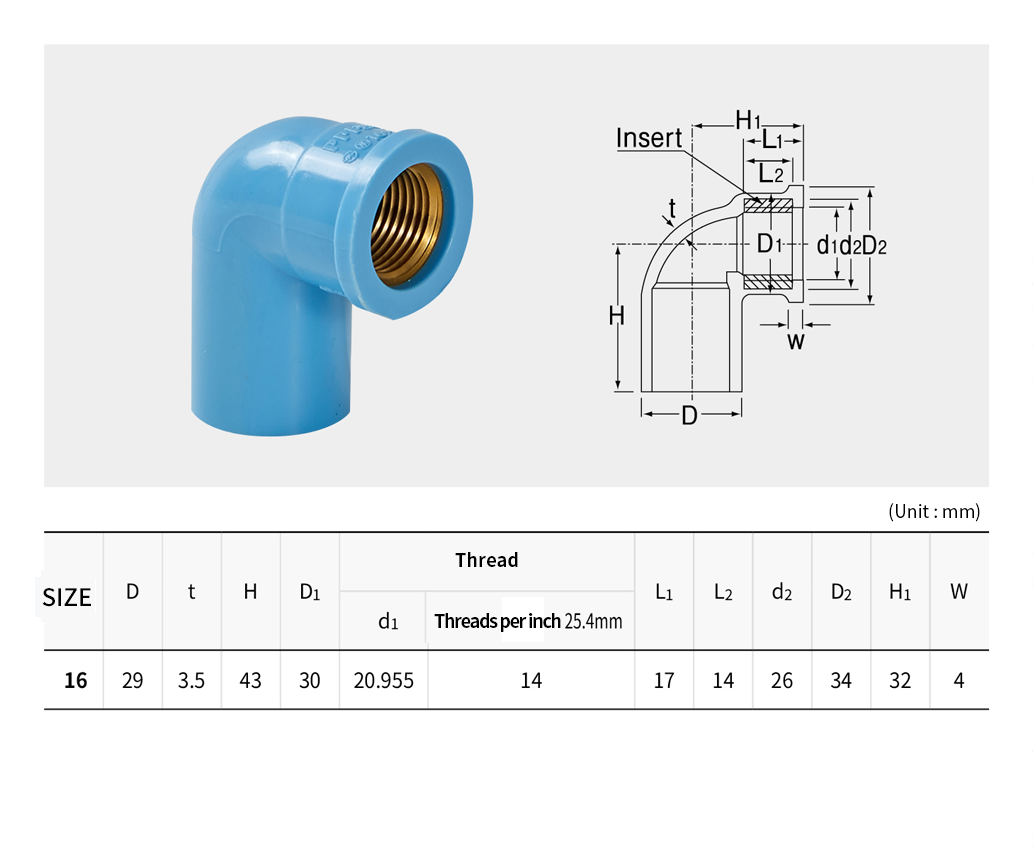

popup Open

HITS-FE

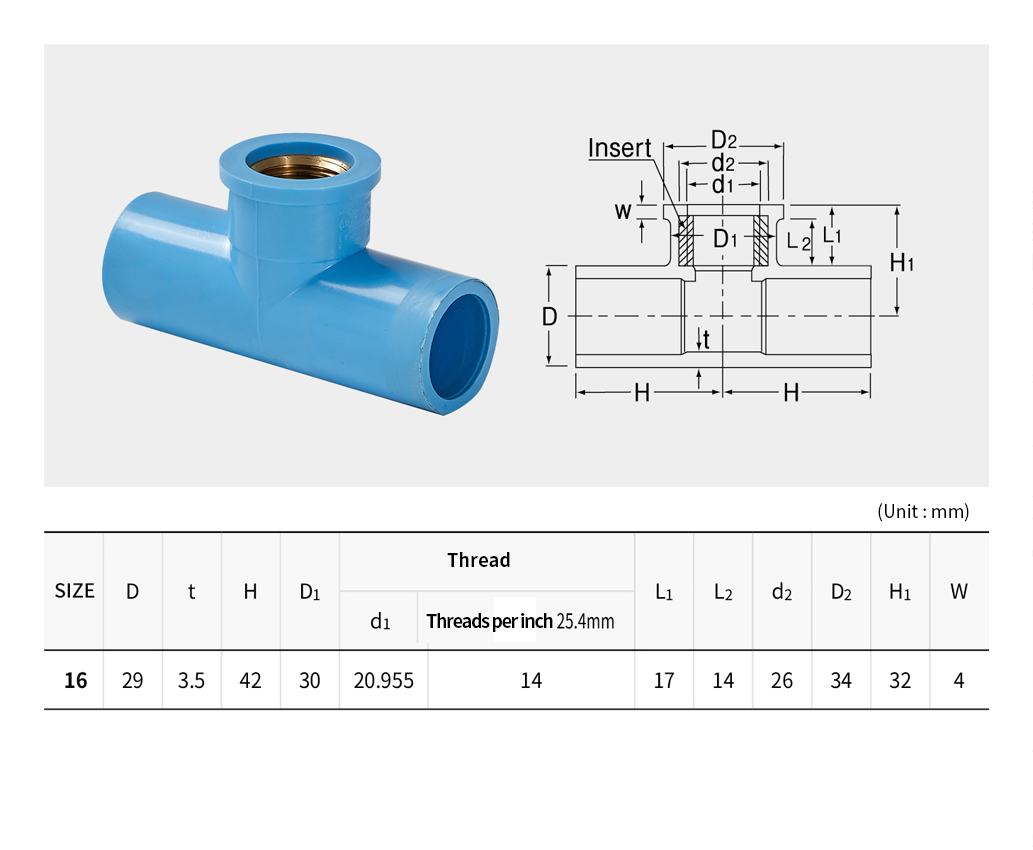

-

popup Open

HITS-FT

-

popup Open

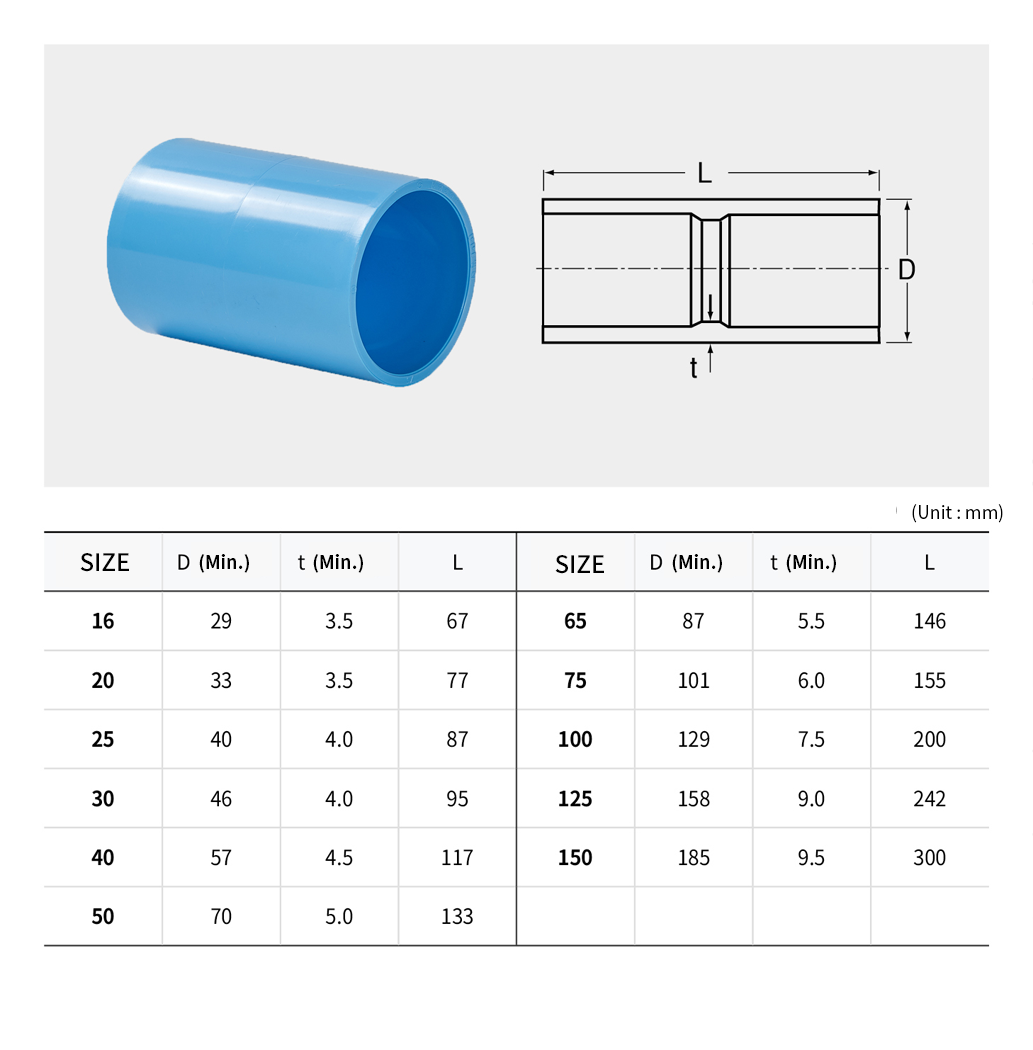

HITS-SOCKET

-

popup Open

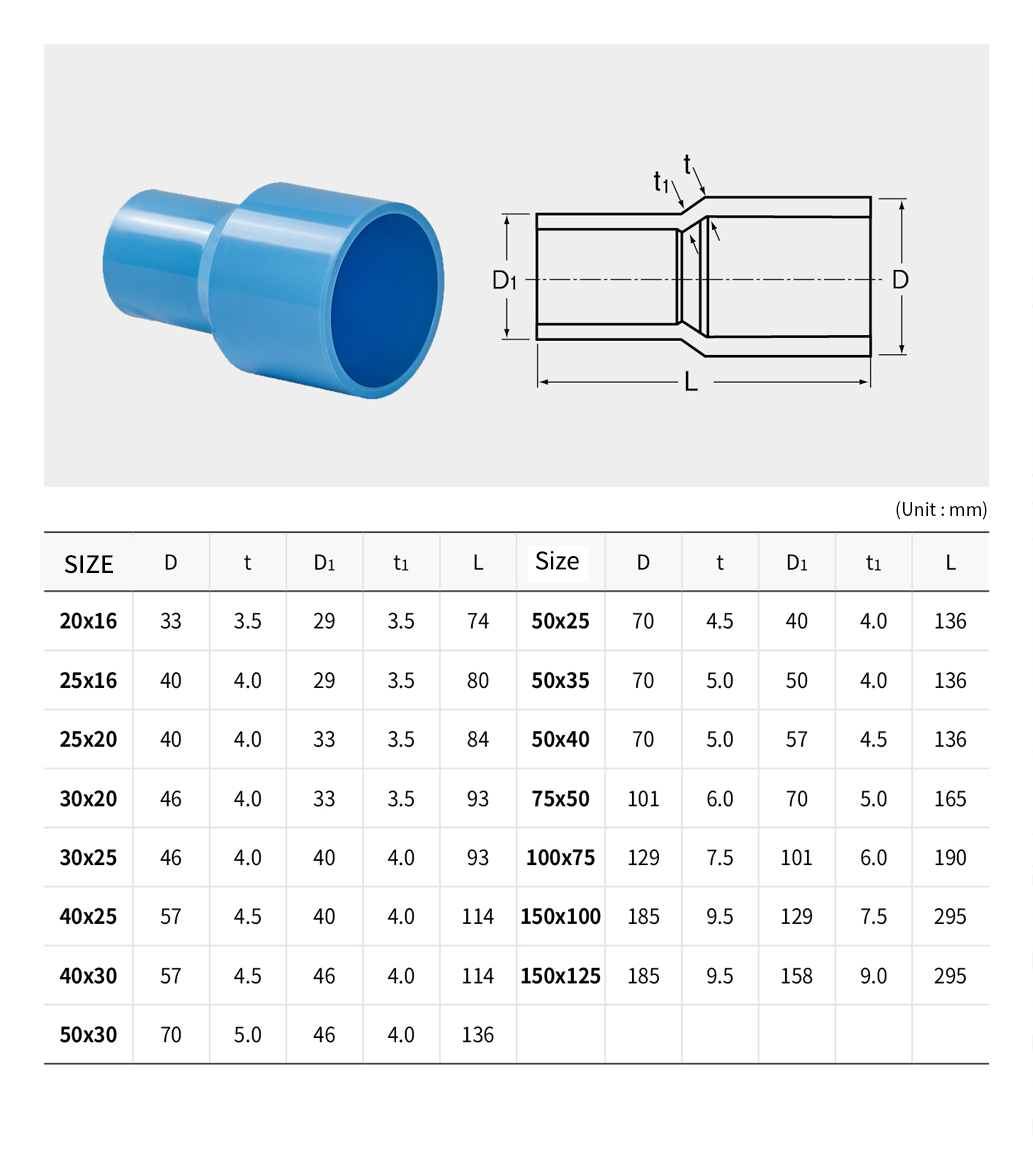

HITS-REDUCER

-

popup Open

HITS-VS

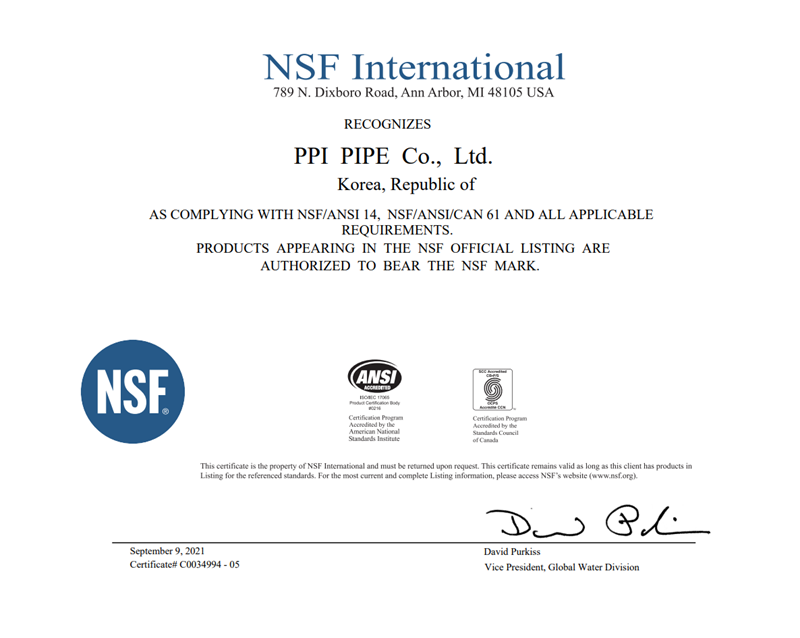

Certification

Click on each certification to see the details.

-

popup Open

NSF International

-

popup Open

American Society For Testing And Materials

-

popup Open

US Army corps of Engineers

-

popup Open

International Management system

-

popup Open

KS Certification

-

popup Open

Korea Certification Sanitary Safety Standards

-

popup Open

ICC Evaluation Servic

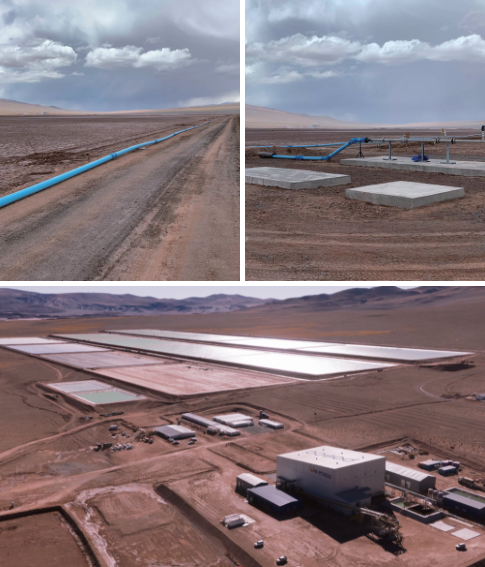

Major References worldwide

-

PosLx Project (POSCO, 9.1 km)

Major Reference in Korea

-

Chemical Wastewater Piping, Yeosu Plant, LG Chem

-

Freshwater Piping, Pohang Steel Mill, POSCO

-

Chemical Wastewater Pipe, Asan Plant, Samsung Display

-

Wastewater Piping, Yeosu Plant, Kolon Water & Energy

-

Wastewater line, Yangsan Plant, Coca-Cola